STRUCTURAL

BOLTING METHODS

TWIST-OFF BOLTS/TC BOLTS

As every method, the RCSC/AISC specification requires Pre-Installation Verification testing that must be conducted onsite with hardware delivered to site. Test results, by the distributor or manufacturer, DO NOT satisfy the specification’s requirements. However, test results appearing on supplier Material Test Reports (MTRs) MUST represent all details of bolts being tested. It is especially important that the MTRs represent a coating when bolts are coated.

This method usually defaults to "twist-off" bolts, sometimes called "tension-control" or TC bolts. These assemblies’ function by calibrating the torque needed to twist off a splined extension manufactured into the bolt shank. Made correctly, the "twist-off" will occur at a bolt pretension above the minimum required.

The main advantage of "twist-off" bolts is that they can be tightened from one side by one person, although bolt installers now realize that regular hex bolts and DTI's can also be installed one-side, one-man, too.

There are several disadvantages to the "twist-off" system:

- Special wrenches are needed.

- TC bolts come in limited lengths and diameters.

- If ASTM F3125/F1852/F2280 Rotational Capacity bolt testing is requested, TC bolts will most likely fail.

- Special connection clearances must be detailed for wrench access.

- Frequently more expensive than hex bolts and DTI's.

- Galvanized twist-off assemblies are in VERY limited supply.

- Field relubrication is prohibited by code.

- Compacting plies must be accomplished prior to twist-off.

- Deterioration of the thread condition for any reason will change the torque-tension relationship, and Kulak has shown in an ASCE paper that in as little as three days out of protected storage, one-third of all the twist-off bolts tested did not develop the required pretension at break-off.

- Additional studies conducted by the University of Toronto show TC bolts performance is negatively affected by temperature and humidity changes.

Bolting Methodology

- Collect only as many bolts to be snugged and tightened during a single shift, from protected storage to prevent lubrication degradation.

- Minimize fastener exposure to the elements and do not disassemble fasteners into individual components. TC bolts are to remain assembled and in as-new condition up until the moment of installation.

- Snug the steel plies, in as many steps as necessary, to bring the steel into firm contact as required by RCSC section 8.1, without twisting the splined end from the fastener. If the end shears off during snugging, the bolt must be discarded and replaced.

- Immediately, or as soon as possible after snugging, apply the shear wrench to each bolt until the tool twists the splined end off and releases the wrench.

- If the joint remains snugged for more than a day or even one shift, additional tension calibrator testing may be required, to assure representative samples have been tested. If excessive time has elapsed, or environmental exposure has occurred, prior to final pretensioning, remove representative samples for re-testing in a tension calibrator (see Pre-Installation Verification).

Inspection

The inspector MUST:

- Verify Pre-Installation Verification has been performed.

- Verify the joint has been snug-tightened.

- Verify the splined ends have not twisted off during snugging operations.

- Verify assemblies in the steel work match the condition of bolts tested during Pre-Installation verification or remove non-similar bolts for additional tension calibrator testing.

- Verify the splined ends have properly severed during installation by the installation tool.

The inspector MUST NOT:

- Accept Pre-Installation test results on new fasteners to represent assemblies that are not in similar condition, due to exposure to the elements.

- Accept TC bolts unassembled or permit individual component replacement.

- Allow relubrication by anyone except the manufacturer.

- Accept TC manufacturer MTR test results in lieu of actual on-site Pre-Installation verification testing.

A pretension that is greater than the [required] value shall not be cause for rejection.5

TC Bolt Advisories

Non-powered manual TC tools DO NOT result in minimum pretension. The tool’s manual will state this fact and there is no known way to correct the flaw. Manual tools are only useful for joints that are snug tight only.

Studies conducted by the University of Toronto in 20046 and 20077 proved:

- TC bolts behave differently in a Hydraulic Tension Calibrators (Skidmore) than they do when installed in steelwork. Therefore, TC bolt testing, with hydraulic load cells, will show results 10% higher than what will be realized in the steelwork.

- Wetting a TC bolt, by rain or otherwise, reduces effective pretension by 10%.

- Changes in temperature negatively affect pretension by 10%.

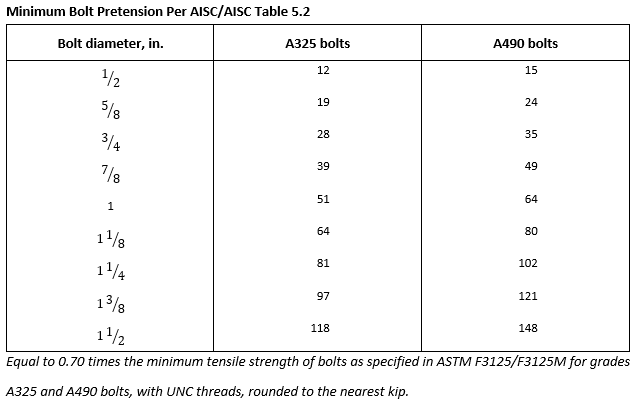

- These issues are cumulative, i.e. a production lot of ¾” A325 TC bolts tested in a skidmore whose dial shows 29 kips will only provide ~ 26 kips when installed in steelwork. If rain wets installed TC bolts, of the same lot, effective installed pretension will be ~23.5 kips. Falling temperature ambient air will result in an additional reduction of effective pretension of 21 kips.

Since the 2005 study was funded by the RCSC, the information described above was presented at the 2007 RCSC Annual Meeting, in Cleveland Ohio by Professor Emeritus of U of T, Peter Birkemoe. Professor Birkemoe made the following recommendations that were not adopted into the RCSC Specification:

- Revise the Specification to have bolts removed from the steelwork for verification.

- Revise the Specification for TC bolts to be required to reach 1.1? times the minimum required pretension in the as-received condition and modify the current

- Pre-Installation verification requirements.

- Add cautionary notes in the commentary about the requirements for cold weather verification and installation.

- Include the “wet” condition as part of the verification requirements.

The above bullet points have been copied from Professor Birkemoe’s RCSC presentation, verbatim. To read the complete 2007 report and meeting minutes, proceed to the RCSC website. The report can be found at: http://boltcouncil.org/files/FinalReportonTCBoltsPhase1.pdf

The Professor Birkemoe’s presentation to the RCSC committee in 2007 can be found by following the link below and reading pages 36 to 50 of the PDF file: http://boltcouncil.org/files/2009RCSCMainMinutesPackage.pdf

Additionally, ASTM 3125, the standard that governs manufacturing and testing of TC bolts (formerly standards F1852 and F2280), requires assembly testing in a “tension measuring device”. For most manufacturers, a hydraulic load cell, such as a Skidmore Wilhelm, is used. Therefore, the pretension values listed on a Material Test Report (MTR) for a TC bolt manufactured lot, should be viewed through the lens of the U of T findings described in number 1, above. Achieved results in steelwork may be 10% less than what is listed on the MTR.

View/Download Twist-Off Bolt Fact Sheet5 RCSC 9.2.3 “A pretension that is greater than specified in table 5.2 shall not be cause for rejection.”

6 Installation behaviour of ASTM F1852 twist-off type tension control bolts. W. Tan, University of Toronto, 2005.

7 INSTALLATION CHARACTERISTICS OF F1852 TWIST-OFF TYPE TENSION CONTROL STRUCTURAL BOLT/NUT/WASHER ASSEMBLIES. V. Maleev, University of Toronto, 2007.

DTIs and TC/Twist Off bolts

While it is uncommon for DTIs to be used with TC bolts, it is permissible to do so. The DTI is added to the assembly, the TC shear wrench is applied to the fastener, and the DTI will confirm if the TC bolt was tightened adequately. Also, Squirter® DTIs combined with TC bolts satisfies AISC/RCSC PIV testing requirements so long as the first three assemblies include the Squirter DTI on the head side of the assembly, and the DTI protrusions are flattened below the calibrated gap. After the first three bolts are tightened, subsequent assemblies can have the Squirter DTIs on either the nut or head side.