STRUCTURAL

BOLTING METHODS

CALIBRATED WRENCH BOLTING METHOD

Calibrated Wrench/Torque

As with every bolt pretensioning method, Calibrated Wrench may only be performed after all steel plies in a connection have been drawn into firm contact, i.e. snug-tightened. Failure to do so will result in inadequate bolt pretension and loose connections.

The Calibrated Wrench pretensioning method is performed by applying a calculated average torque value to fasteners based on daily testing representative fastener assembly samples using the exact configuration of installation tools and power supplies under as nearly identical conditions as possible as actual installation conditions, within one day or less. The representative fastener assembly samples are primarily defined by production lot combination of each assembly and further divided by fastener condition, individual component state, jobsite environment, time removed from protective storage and every arrangement thereof. The use of formulas or charts with specific values is not permitted. Counting seconds, particular sounds, vibrations, or lack thereof, while tightening are not acceptable substitutions for actual daily testing.

Except for projects having very few bolt combinations that will be pretensioned in a minimal number of days, calibrated wrench is the most expensive method to pretension bolts. Torque testing will be nearly constant since all test results apply only to a specific tool, a single unique bolt assembly, fully pretensioned on the day of testing. Torque charts and equations are expressly forbidden by the RCSC/AISC specification; “Torque values determined from tables or from equations that claim to relate torque to pretension without verification shall not be used.” (AISC/RCSC 8.2.2)

Bolting Methodology

RCSC/AISC 8.2.2. Calibrated Wrench Pretensioning: The Pre-Installation verification procedures specified in Section 7 shall be performed daily for the calibration of the installation wrench. Torque values determined from tables or from equations that claim to relate torque to pretension without verification shall not be used.

The phrase “without verification” means a tension calibrator must be employed to verify enough torque has been applied. Since DuraSquirt® DTIs are bolt tension measurement devices4, an alternative to nonstop testing is possible if DuraSquirt® DTIs are used in conjunction with Calibrated Wrench.

DuraSquirt® DTIs provide verification necessary regardless of tool, torque applied or bolt condition. If a DuraSquirt® DTI completely emits orange indicating material at all the Squirt™ locations, enough torque has been applied. If the DTI fully emits orange indicating material at the Squirt™ location, it is properly tensioned.

For a full description of this procedure follow the link below:

https://www.appliedbolting.com/pdf/DuraSquirt-RCSC 2.12.pdf

Day 1 Fastener Sampling:

Collect 3 samples of all complete fastener assemblies based on each combination of diameter, grade, length and production LOT and collect additional complete sample assemblies when:

- The lot of any component of the fastener assembly is changed.

- The finish and tolerance on the bolt and nut threads changes.

- The uniformity, degree and condition of lubrication changes.

- The shop or job-site conditions that contribute to dust and dirt or corrosion on the threads change.

- The friction that exists to a varying degree between the turned element (the nut face or bearing area of the bolt head) and the supporting surface changes.

- The lot of any component of the fastener assembly is re-lubricated.

- When significant differences are noted in the surface condition of the bolt threads, nuts or washers.

- The variability of the air supply parameters on impact wrenches that results from the length of air lines or number of wrenches operating from the same source.

- The condition, lubrication and power supply for the torque wrench, which may change within a work shift.

- The repeatability of the performance of any wrench that senses or responds to the level of the applied torque.

- When any major component of the wrench including lubrication, hose and air supply are altered.

- Every tool and supply and/or combination of tools and supply.

- For every permutation of items 8 through 12.

Collect every permutation of items 1 through 7 daily adding additional 3 complete sample assemblies and tests when the following factors are encountered

Day 1 of Testing & Bolting Operations:

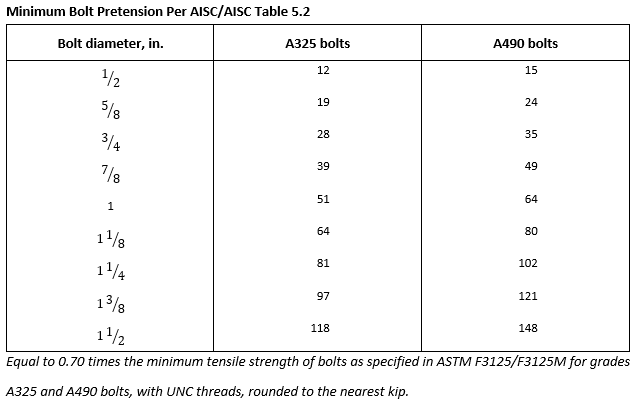

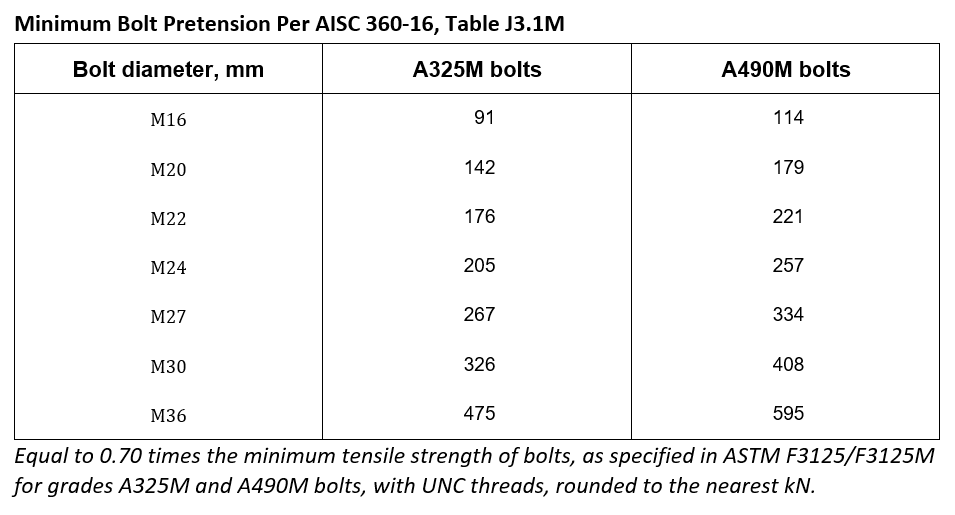

Conduct the Pre-Installation Verification procedure described in section 7 of the Research Council on Structural Connection's (RCSC) Specification for Structural Joints Using High Strength Bolts on all samples collected per the previous section.- Verify the resulting pretension meets or exceeds the minimum required bolt pretension as listed in table 7.1.

- Record the torque required to achieve step 1 above and average the 3 values.

- Snug the steel plies of the connection whose sample group has completed testing.

- Using the highest torque value recorded for a specific sample group; apply recorded torque to all fasteners' representatives defined by the sample group within a reasonable time* and while all conditions remain similar to that observed during testing or repeat steps 1 through 3 if conditions are not similar. NOTE: the unturned element must be restrained from rotating during this operation.

- Repeat number 1 - 4 for every combination of installation components (wrenches, hoses, compressors etc.) that will be performing the bolting operations for Day 1.

Day 2 and every day thereafter:

- Disregard all torque values calculated from previous Day of Fastener Sampling described here if applicable.

- Repeat Day 1 of Fastener Sampling described here.

- Repeat Day 1 of Testing & Bolting operations described here.

- Repeat Step 1 above of this series of instructions (i.e. Day 2 and every day thereafter).

Inspection:

Observe that all sampling and testing described here has been conducted. Routinely confirm specific torque results for precise hardware combinations are only applied using the exact equipment that was used during testing.

Inspection of installed bolts must be conducted by watching installation personnel apply the predetermined torque to bolts in the steelwork. The use of any type of torque inspection wrench is not permitted:

AISC/RCSC 16.2-9.2.2:

(2) Verify by routine observation that the snug-tight condition has been achieved in accordance with Section 8.1; and

(3) Verify by routine observation that the bolting crew subsequently applies the calibrated wrench to the nut. No further evidence of conformity is required.

Time elapsed between unpacking, sampling, testing, snugging and pretensioning to be minimal or all affected hardware must be re-tested. Fasteners installed, but not fully pretensioned, within a reasonable time5, must be removed from the work, separated according to Day 1 Sampling described earlier and fully tested per Day 1 Testing & Bolting Operations described here. A pretension that is greater than the [required] value shall not be cause for rejection.6

Warning: Calibrated Wrench IS only suited for small projects having few production LOTs, lengths, and diameters of components, to be installed using the minimum number electric torque wrenches (or similarly reliable) possible that can complete all bolting operations (unpacking, testing, stuffing, snugging, pretensioning & inspecting) in a single day or less. Calibrated Wrench or torque installation is specifically prohibited for any project that references the Canadian Institute of Steel Construction's (CISC) Handbook of Steel Construction.

DTIs and Calibrated Wrench/Torque

The rigorous pre-installation verification (PIV) testing, required by calibrated wrench, can be avoided by adding a DTI to the assembly. In fact, standalone PIV testing, with a hydraulic tension measurement device or otherwise, can be replaced by tightening using torque verification lots of DTIs with a determined calibration gap.

While calibrated wrench is complicated per the AISC/RCSC spec, it doesn’t need to be. Per 8.2.2:

Torque values determined from tables or from equations that claim to relate torque to pretension without verification shall not be used.

The phrase “without verification” means one could use a torque value if it can be verified. The AISC/RCSC preinstallation verification section describes DTIs as bolt tension measurement devices that can be used to verify calibrated wrench. Per the first sentence on page 16.2-59:

Direct tension indicators (DTIs) may be used as bolt tension measurement devices, except in the case of the turn-of-nut method and the combined method.

Further down it describes how to promote any type of DTI into a “verification lot DTI” with a predetermined “calibrated gap”. Since we (Applied Bolting) determine the calibrated gap using our ASTM F606 tester, the calibrated gap appears on every Squirter® DTI’s material test report (MTR). Also, because we design our Squirter® DTI to expel orange media 15%-20% above the minimum required preinstallation verification testing, all one must do is apply enough torque to deploy the media, and the bolt is considered tested, in accordance with section 7. It is installing a bolt tension measuring device on every bolt, essentially, preinstallation testing every bolt, as they are installed. Employing this method is as simple as:

- Snug the connection.

- Apply enough torque to deploy the orange media, i.e., reducing the verification lot DTI’s gap below the calibrated gap.

- After 3 bolts are tightened, preinstallation verification per AISC/RCSC, section 7 has been satisfied.

Technically, the first three bolts should have the DTI on the head side, but if one is going to represent the assembly being installed, it can be proven to work on the nut side. The method of using a DTI as a bolt tension measuring device has been in the RCSC specification since 2009, but it has not been implemented as much as it should be. Most people don’t realize it is perfectly acceptable to apply section 7 using solid steel. In addition to what I describe for DTIs, it has always been permissible to conduct preinstallation for Turn of Nut without a bolt tension measuring device. Per 16.2-59, in about the middle of the page:

For turn-of-nut method pre-installation verification of bolts too short to fit into a bolt tension measurement device, installing the bolting assembly in a steel plate with the proper size hole and applying the required turns is adequate.

Having a hydraulic, or similar bolt tension measuring device available for diagnosing problems, as they are encountered, is still a good idea, but projects should exploit “the DTI as a bolt tension measuring device” allowance more often.

4RCSC/AISC-348-15 Section 7.1 “Direct tension indicators (DTIs) may be used as bolt tension measurement devices”

5Reasonable time shall not exceed a single day but may be less than one work shift depending on specific project conditions described herein.

6RCSC 9.2.2 “A pretension that is greater than the value specified in Table 5.2 shall not be cause for rejection. The use of a torque greater than the minimum installation torque shall not be cause for rejection.”